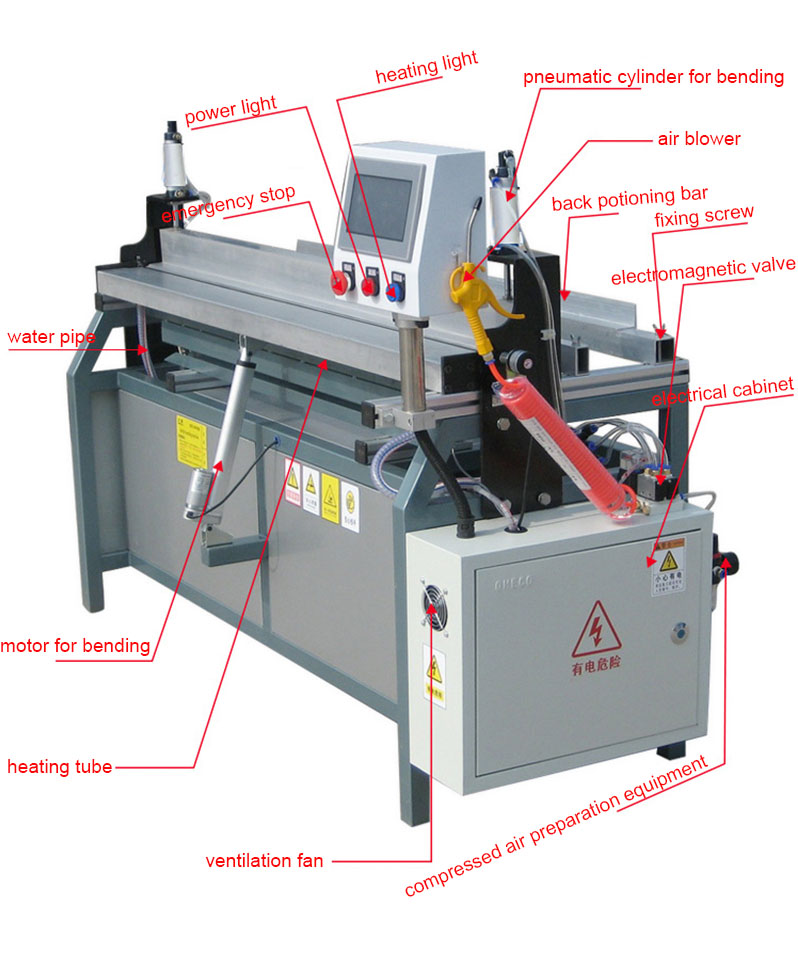

Full Automatic CNC Acrylic Bending Machine

-

Schematic Diagram for Main Components

-

Specification

| Model No. | BT-2400UB (2440mm with single under-heating tube) |

| Degree of Automation | Fully automatic, controlled by numerical with PLC touchscreen |

| Operation Language | English and Chinese, switchable according to your request |

| Working Length | 0~2440mm |

| Material Width | Unlimited |

| Range of Angle Formed | 60~180° (less 60°, bend angle manually) |

| Working Thickness | 0~8mm |

| Heating Temperature | 0~650℃ (adjustable upon request) |

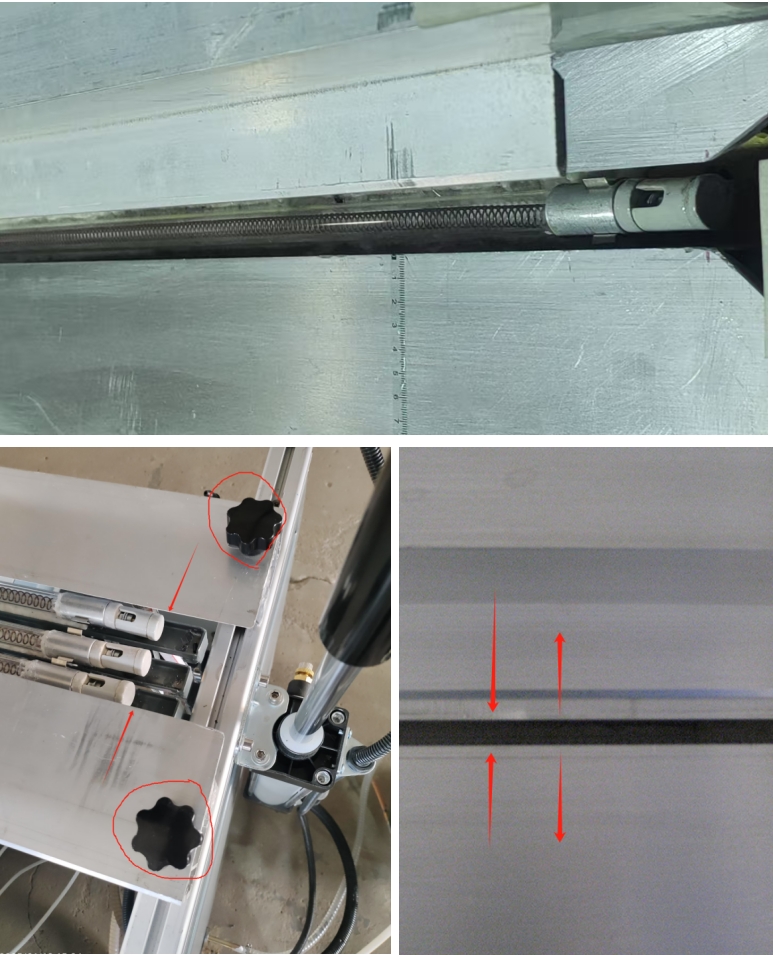

| Heating Gap | 0~50mm (adjustable according to material thickness and R angle request) |

| Heating Time for each angle | 7-120s, depended on material thickness |

| Bending Time for each angle | 4s |

| Cooling Time for each angle | 7-120s, depended on material thickness |

| Heating Mode | Non-contact infrared heating |

| Heating Instrument | High quality transparent tube with 2080 heating wire |

| Heating Tube Power | 3kw |

| Heating Tube Number | 1pc |

| Main Motor Power | 2kw |

| Max. Power | 5kw |

| Voltage | 1 phase AC220V+/-10% |

| Worktable Material | Super thick cast Aluminium |

| Distance between heating tube and material | adjustable |

| Arc-angle Bending (YES / NO) | YES |

| V-shaped angle Bending(YES / NO) | YES |

| Cooling Mode | By water |

| Dynamic for Worktable folding | Pneumatic |

| Worktable Folding Pressure | 150kg |

| Worktable Working Speed | 1s~10s / time |

| Movement Speed of pneumatic | Adjustable |

| Capacity of Water Tank | 50L |

| Machine Dimension (LxWxH) | 274x70x120cm |

| Package Dimension (LxWxH) | 295x78x125cm, 2.88CBM |

| Weight | 320kg |

-

Applicable material and industries

The machine can process almost all kinds of hard plastic plates, including but not limited to acrylic plate, plexiglass, ABS board, PVC plate, PC sunshine board, PP, PET, etc

It is widely used in school laboratories, model designing, decoration works, placards, tags, package pillar, protect the corner, fish tank, display rack, shelves, light box, arts and crafts, machine moving door, etc.

-

Feature

1. Numerical control. The workflow is fully controlled by the industrial control board with PLC touchscreen. Compared with manual machine and digital-control machines, it has huge advantages:

1) The heating time, heating temperature, bending angle, etc, can be set and adjusted on the touchscreen, fully automatic and high working efficiency.

2) Labor cost is lower because the material is fixed and bent automatically by the machine, one worker can monitor many machines meantime.

3) The accuracy of bending angle is higher. It’s controlled and processed by the machine automatically, less error than manually.

4) Manual working status and Automatic working status, English and Chinese language, switchable upon your request.

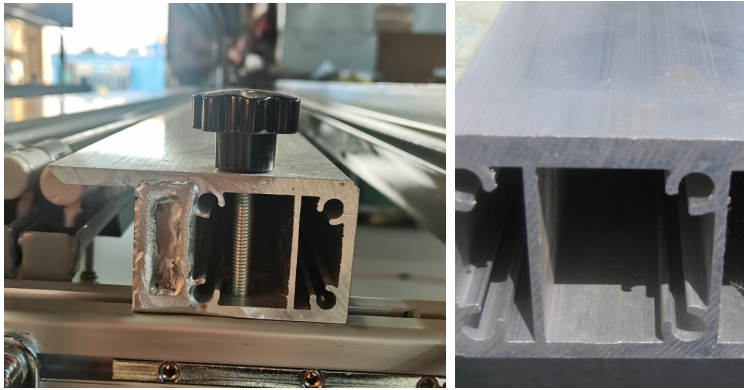

2.The workable and water circulation path is made of super thick cast aluminium.

1) Since it is flat and smooth, it will not scratch the material sheet.

2) Good cooling effect, speed up the cooling rate of the sheet.

3) Not prone to deformation, more durable and achieve perfect working effect.

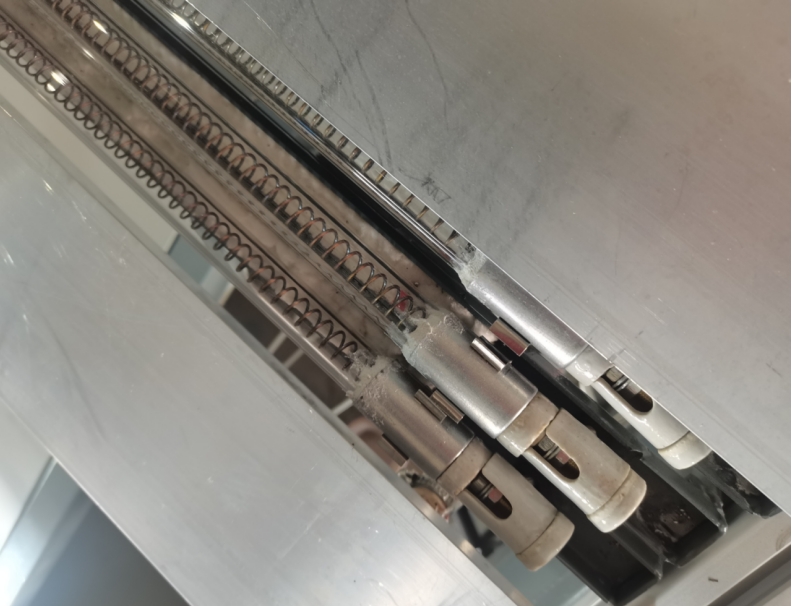

3. It’s equipped with the high quality transparent glass tube with 2080 heating wire, high heating efficiency, even heating, and linear heating status.

4. The heating gap is adjustable according to material thickness and the R angle request, normally it should be 3~4 times of material thickness. E.g. if the acrylic sheet is 3mm, the heating gap width should be 9~12mm. Large gap width, larger R angle degree.

5.Cooled by automatic water circulation, to make sure the heating area is linear.

6. The worktable folding movement is controlled by pneumatic system, accurate positioning and high working efficiency.

7. The back positioning bar is helpful for keeping uniform in mass production alignment, and does not need to positioning and aligning for every single work piece.

8. The machine has dual leakage protectors, safer operation.

9. Equipped with the air-blower.It can blow away dust and debris from the work surface and keep it clean and tidy.

10. Heater voltage conversion function. In mass production, you can keep the heater power-on function to reduce the preheating time of the heating tube. For single-piece production, choose the power-off function of the heater to save electricity.

11. Heating temperature is adjustable according to different material and thickness etc, so to get the perfect processing quality.

12. Heater lifting and descending function. When heating, the heater rises to heat the sheet. When the sheet is set, the heater descends away from the sheet and speeds up the cooling of the sheet.

-

Warranty

2 years dating from the machine is received by buyer.

-

Contact us to get more details and techical support

-

Economical But Practical Desktop Plexiglass Ben...

-

High quality automatic 3-tubes plastic acrylic ...

-

China Supplier acrylic bend art bender desktop ...

-

Best Selling Products channel letter bending ma...

-

Acrylic Bender Hot Bender V-Shape Bending Machine

-

Top Quality Manual Acrylic Sheet Bending Machine